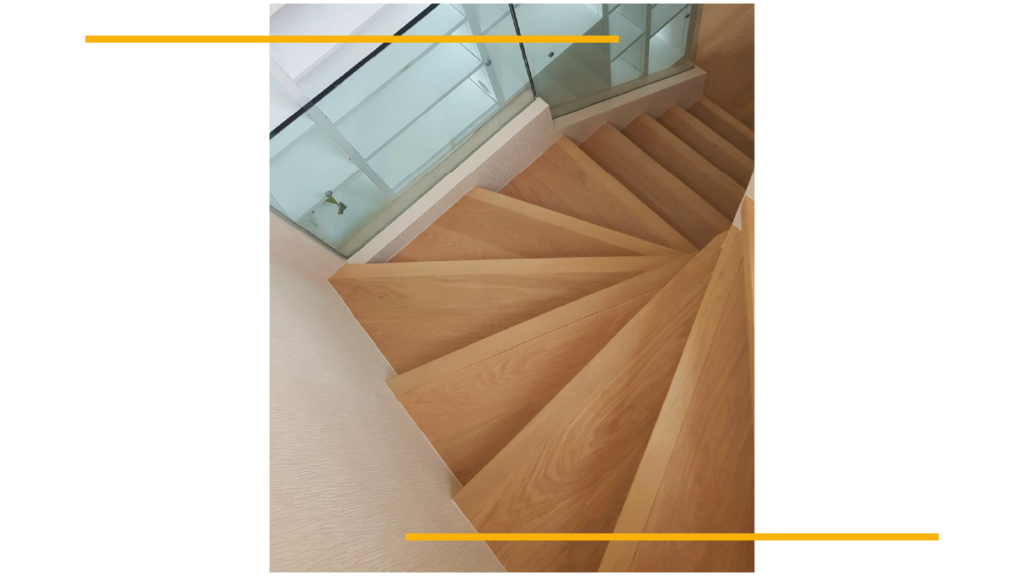

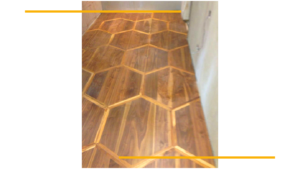

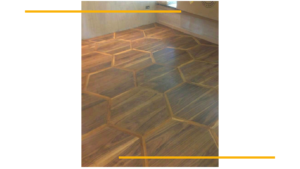

Solid Wood Flooring

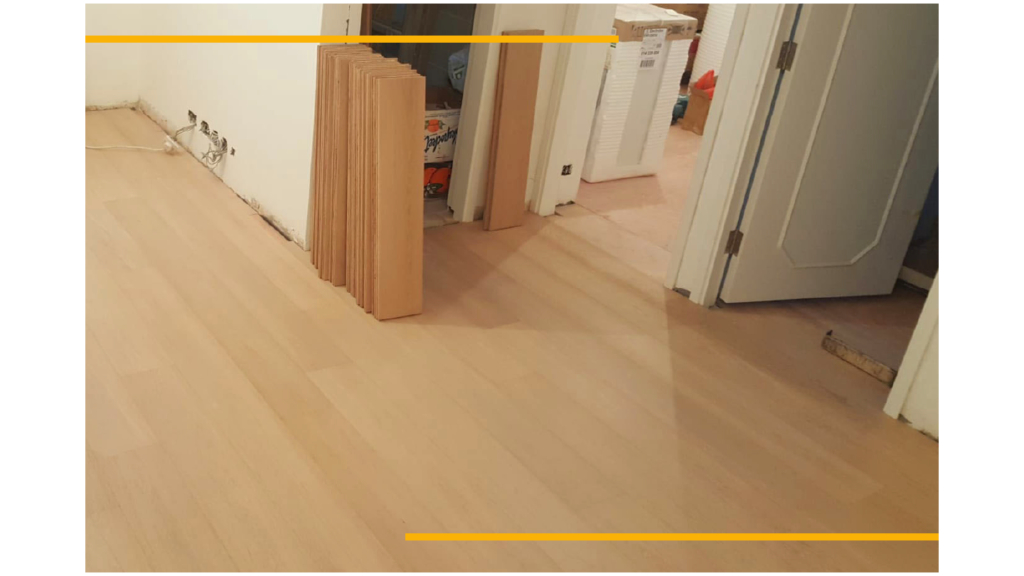

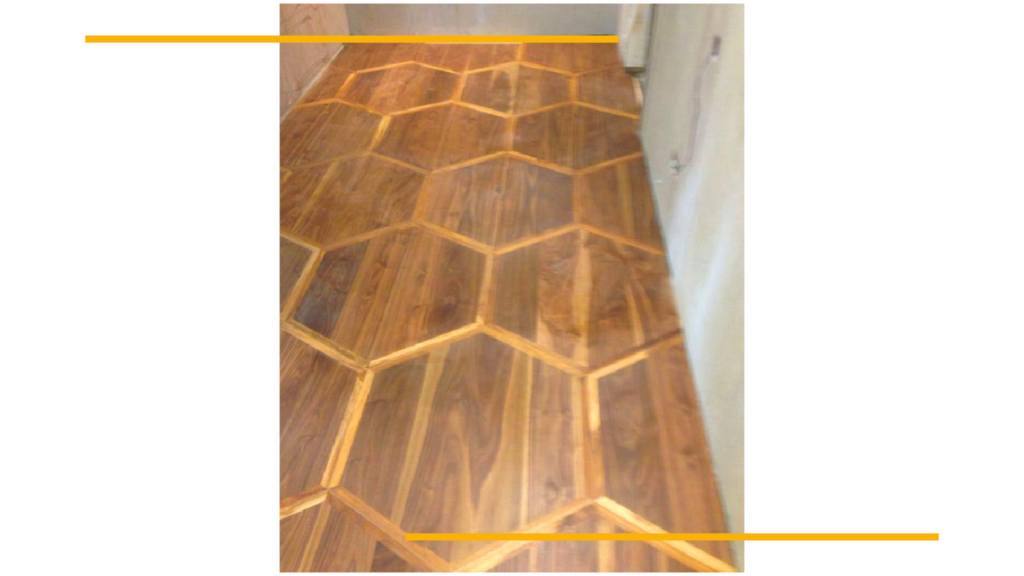

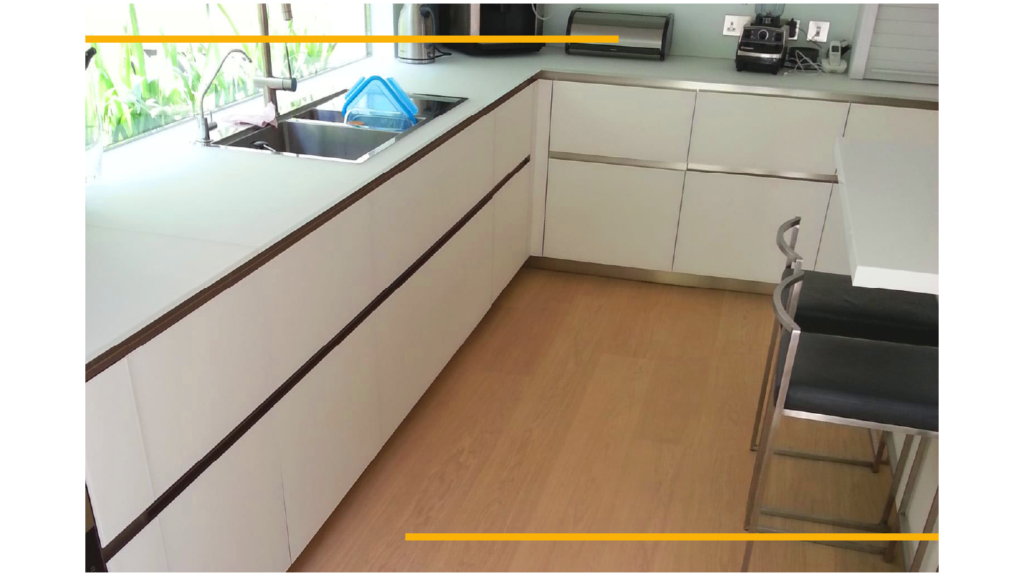

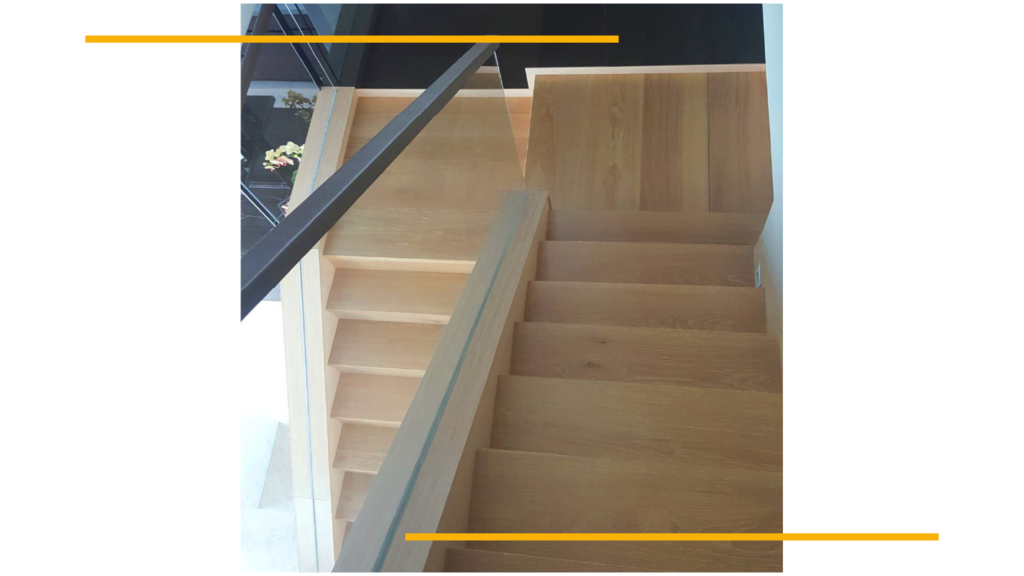

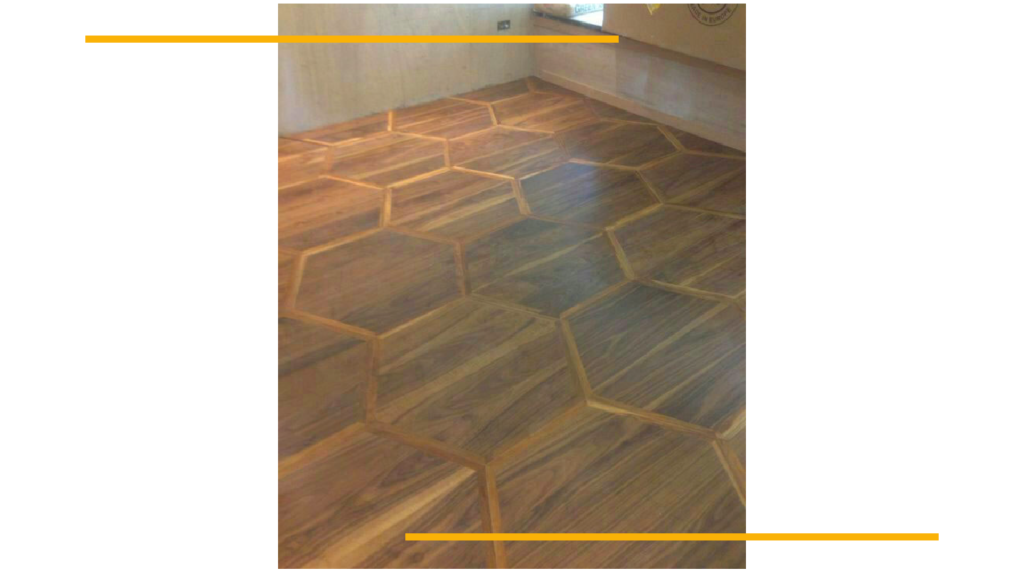

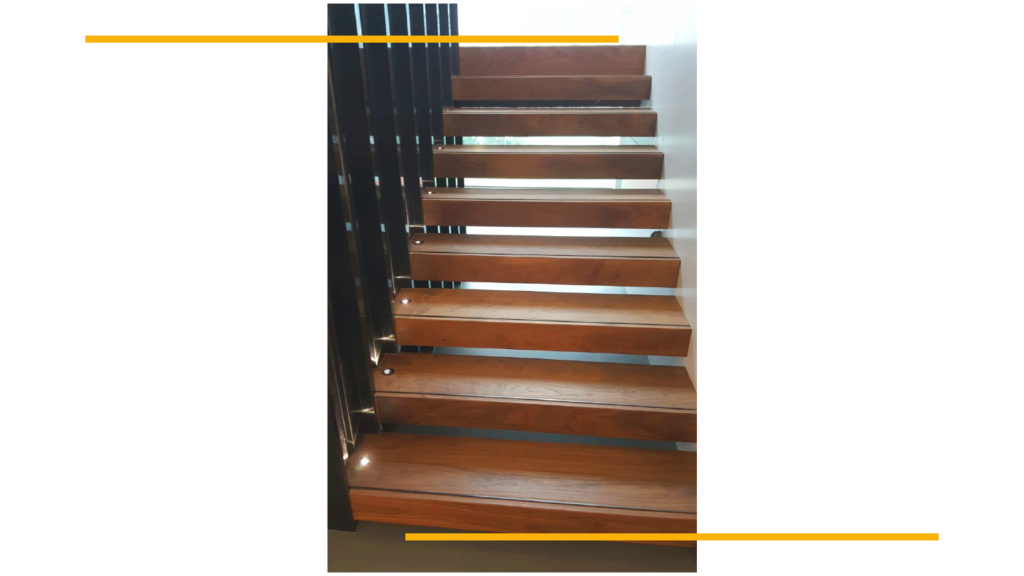

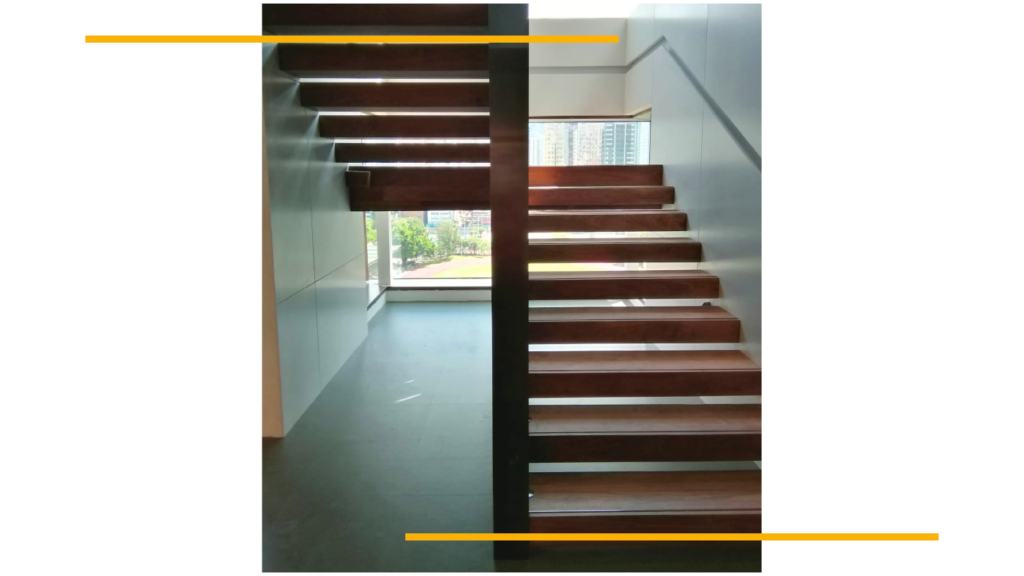

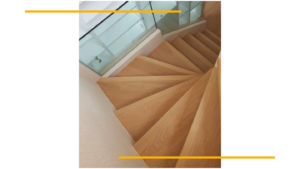

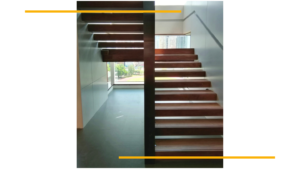

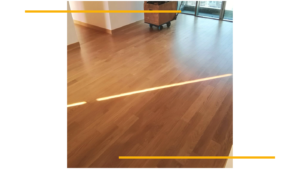

Solid wood flooring can be divided into two types: indoor wood flooring and outdoor wood flooringbecause the quality of some wood itself is different. Some solid wood can only be used indoor, such as maple, beech, oak, walnut, cherrywood etc. Some are suitable as for outdoor wood flooring, such as IPE, rosewood, teak, yellow balau, Hopea spp wood, etc. Indoor and outdoor solid wood floors give customers a feeling of natural, warm, textured and top grade.

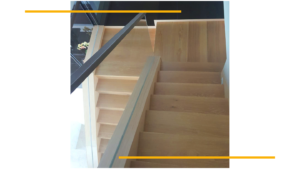

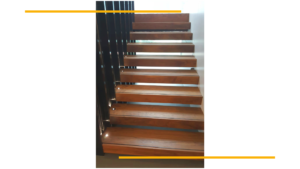

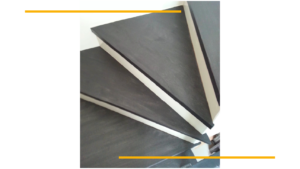

In the production process of indoor solid wood flooring, the log materials are first cut into different sizes, then undergone drying and thermostatic process. First, moisture in the wood are extracted to stabilize the moisture content index, and then dried. After the wood surface is shaped and cut to a suitable size, the wood board will then be sanded and the tongue-and-grooves are cut out. Wood boards with large cracks, insect holes, dead joints, etc are not suitabe for making floorings. After spraying paint, drying and shaping, the indoor solid wood flooring production process is completed.

As for the production process of outdoor wood floorings, high density, high hardness and oily wood should be preferred, since they are used in the open-air environment. After drying, constant temperature, shaping, cutting into different suitable sizes and cutting out grooves, a UV-proof, waterproof and harmless and environmentally-friendly outdoor paint is then applied to 6 sizes of the outdoor wood, to ensure that rainwater can not hack inside. You can apply environmentally-friendly paint by yourself in the future to keep it looking new over time.